Location: Melbourne

Building: Melbourne Convention and Exhibition Centre

Year: 2019

Value: $2.800.000

Video Overview (from the NECA Awards 2019)

Project Overview

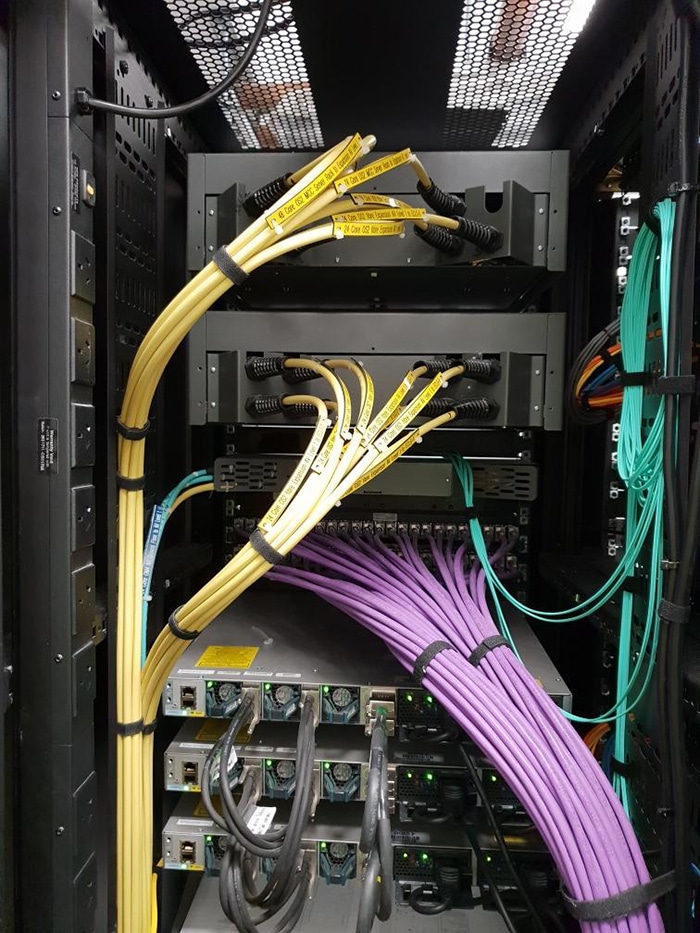

Newscom were engaged to design, supply and install the ICT and Audio Visual infrastructure cabling for the new Melbourne Convention and Exhibition Centre Expansion inclusive of the construction of 12 new floor distributor cupboards each comprising of two full height network racks to house fibre optic backbone cabling to the existing two server rooms, the two new Audio Visual control rooms, Siemon category 6A shielded structured cabling (more information here) and AFL Global fibre optic cabling to the various outlet locations in the facility including floor, wall and ceiling box locations. Key project points include:

- Over 3,000 category 6A data outlets

- Over 46 kilometres of fibre optic cabling (backbone and horizontal links)

- Over 3,600 individual cores of terminated fibre optic cabling.

- Over 200 floor and wall box locations each with 6 x data outlets and 6 cores of fibre optic cable.

- 170 ceiling box locations with 3 x data outlets and 4 cores of fibre optic cable, all located within the roof structure over 20 metres from floor level.

Many of the fibre backbone links were over 700 metres long due to the location of the existing server rooms in the adjacent facility.

Each floor distributor cupboard was provisioned with 2 x 36 core singlemode fibre optic cables, one from each of the facility’s existing server rooms, 2 x 24 core singlemode fibre optic cables, each from the facility’s two new audio visual control rooms and a 25 pair voice tie cable for distribution of analogue services though out the facility.

Installation of all the wireless network access points including 36 custom made 3 metre x 3 metre brackets to support the high level access points 20 metres in the roof structure of the exhibition hall, each unit with 4 x external antennas

Design and manufacture of 180 custom made enclosures to house 6 x data and 6 x fibre connections within the sub floor space of the exhibition hall space to allow exhibitors flexibility with network provisions to their space.

Commercial Factors

Are large portion of the project involved the supply and install of 6 core fibre optic cabling into over 400 floor, wall and ceiling box locations for both the ICT and audio visual systems. The difficulties with terminating cabling out in the field in a construction environment meant the best and most cost effective solution was to have the various fibre cables site measured, factory terminated and delivered to site with protective sleeves over the ends of the cable ready for installation. Our supplier AFL Global was able to turn these around with a one week lead time to ensure we were able to rough in the cabling as areas were available to us.

The audio visual infrastructure cabling specified either 4 or 8 analogue audio tie cables from the AV control rooms out to the various meeting and function rooms. We were able to source an all in one cable which combined either 4 or 8 individual cables into the one sheath, saving considerable time and cost during installation.

Technical and Innovation

The main exhibition space in the expansion comprises of over 9,000 square metres with 180 floor boxes evenly spaced throughout the floor and 168 located within the roof structure above. Each of the floor and ceiling boxes is supplied with fibre optic and category 6A shielded cabling to cater for the needs of the exhibitors. The floor boxes are basically an opening in the floor with a steel cover so finding a termination solution for our cabling posed a few challenges. We met with a supplier and designed a lockable enclosure that would be able to accommodate both the fibre and copper cabling in a steel box that we could mount on a bespoke bracket to present the outlets readily accessible once the floor box cover was removed. We were able to mount the enclosures to our bracket and affix them to the underside of the floor opening and connect the cabling prior to the concrete slab being poured, further saving time later.

Installation of the 36 high density wireless access points within the exhibition hall ceiling space posed further challenges as the external panel antennas had to be place lower than the unit itself and be positioned centrally between to ceiling louvres. This bespoke bracket had to also factor in the 15 degree roof incline to position the antennas vertical to the structure. The 144 antennas also required custom designed fabric cover

Fibre backbone cabling back to the existing server room in the Exhibition building also had no known pathway designed so by studying existing drawings we were able to identify a location were we could have 2 x 1800mm long 100mm wide core holes penetrate through the existing structure into the existing services tunnel to provide access for our cabling and spare capacity for the future.

Quality

Inspection test plans were created for all works zones to identify every single cable installed in the project whether it be backbone cabling or horizontal link to ensure each stage of the installation process was documented from installation through to commissioning and labeling.

A monthly walk through with the consultant team ensured that quality was maintained throughout the installation process and independent reviews held prior to each staged handover of the facility

Management

A project of this size and nature, one of the largest ever undertaken by Newscom meant that the attention to detail both in the office and on site to ensure the smooth running of the project from design, purchasing and procurement through to installation and commissioning followed a steady sequence of events.

Due to the project time frame no delays could occur with procurement as installation could not occur once areas were closed up. Working carefully with our site manager we ensured that all materials were available on site when needed to keep up with the project timelines.

Many items had to be procured from overseas so large orders were placed for all of these materials and stored on site in a shipping container.

Being on site at least three times a week for project meetings and site inspections to ensure all labour requirements were met for the project.

Workplace Health and Safety

With the industry standards being raised in all areas including Health and Safety Newscom decided seven years ago that this area was a specialized part of the business and decided to have all our Health and Safety measures in the company re assessed. The Newscom Health and safety document with all our SWMS, MSDS and risk assessment in one. All Newscom staff have been trained in using this system on all projects to make sure our staff are all conforming to the national health and safety standards.

Further development of the WHS package is undertaken prior to commencement on site to accommodate for site specific issues such as high level works, confined spaces or other factors that may be encountered over the course of the project.

When working at heights all workers were provided with lanyards to fit to all tools to prevent any risk of injury to workers below. Barricades were also provided around working areas and also coordinated onsite to ensure further risk was minimised.

As the project time frame was limited it was operating for 24 hours a day on a weekly basis and shift work from 11.00pm to 7.00am was also introduced so working at heights in the main exhibition space was largely performed during these hours when the minimum amount of workers was on site.